Pre-painted galvanized iron (PPGI) sheets have become a cornerstone material in both industrial and construction sectors due to their durability, versatility, and aesthetic appeal. These coated steel sheets combine the strength of galvanized steel with the protective and decorative benefits of a pre-painted surface, making them ideal for a wide range of applications—from roofing and cladding to appliances and automotive components. As industries continue to seek sustainable, long-lasting materials, PPGI sheets stand out as a superior choice.

Understanding PPGI Sheets and Their Global Demand

PPGI sheets are manufactured by applying a protective zinc coating to steel, followed by multiple layers of paint or organic coatings that enhance both appearance and performance. This process not only improves the corrosion resistance of the material but also extends its lifespan, even in harsh environments. With increasing global infrastructure development and industrial expansion, the demand for PPGI sheets continues to rise steadily across continents.

Among the leading producers of premium galvanized and color-coated steel products, High-Quality Ppgi Sheet suppliers from China have gained international recognition for their advanced manufacturing processes and consistent product standards. Utilizing automated coating lines, precision color matching, and strict quality control systems, these manufacturers ensure that each PPGI sheet meets international specifications and performs reliably across a variety of industrial and architectural applications.

Key Features and Benefits of PPGI Sheets

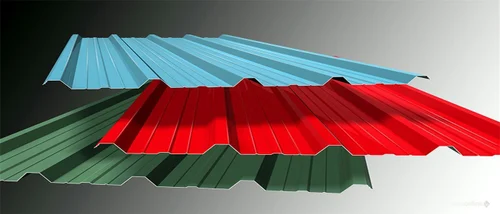

PPGI sheets are highly valued for their unique combination of strength, protection, and design flexibility. The zinc coating acts as a barrier against oxidation and corrosion, while the paint layer adds an extra shield and visual enhancement. These characteristics make PPGI sheets suitable for projects that require both aesthetic appeal and functional performance.

Some of the key advantages include:

-

Superior Corrosion Resistance: The galvanized layer provides excellent protection against rust and weathering, making PPGI sheets ideal for outdoor use.

-

Long Lifespan: With proper maintenance, PPGI sheets can last for decades without significant deterioration.

-

Aesthetic Versatility: Available in a wide range of colors, finishes, and patterns, PPGI sheets allow for creative architectural designs.

-

Ease of Installation: Lightweight yet strong, these sheets are easy to handle, transport, and install, reducing overall project costs.

-

Environmental Sustainability: Many PPGI sheets are produced using eco-friendly coatings and recyclable base materials, contributing to sustainable construction practices.

Manufacturing Process of PPGI Sheets

The production of PPGI sheets involves several precise stages, starting with the preparation of the base steel coil. The steel is first cleaned and pre-treated to remove impurities before being hot-dipped in molten zinc to form a uniform galvanized layer. After galvanization, the sheet undergoes a chemical coating process to improve paint adhesion.

Next, the color coating is applied using a continuous coil coating method, ensuring even distribution of paint and a flawless surface finish. The coated sheet is then baked and cooled under controlled conditions to achieve maximum adhesion and durability. This advanced process ensures that PPGI sheets maintain their gloss, color uniformity, and resistance to UV rays and abrasion.

Applications Across Multiple Industries

The versatility of PPGI sheets has made them indispensable across numerous sectors. In construction, they are used for roofing, wall cladding, ceilings, and pre-engineered building structures due to their strength and weather resistance. Industrial facilities utilize PPGI sheets for warehouses, factories, and cold storage units, where temperature regulation and corrosion resistance are critical.

In the automotive industry, PPGI sheets serve as components for body panels, engine covers, and interior structures. They are also used in home appliances such as refrigerators, washing machines, and air conditioners for their sleek appearance and easy maintenance. Additionally, agricultural and commercial projects employ these sheets for shelters, fencing, and equipment enclosures, where both durability and cost-efficiency are essential.

Quality Standards and Performance Testing

Leading manufacturers ensure that PPGI sheets meet international quality certifications such as ISO, ASTM, JIS, and EN standards. Each batch undergoes rigorous testing, including adhesion, bending, impact, and salt spray tests, to verify its durability and performance under various environmental conditions. The coatings are designed to resist fading, chalking, and peeling even after prolonged exposure to sunlight and moisture.

Furthermore, modern production facilities utilize advanced color measurement and control systems to ensure uniformity across large orders, providing consistency for architects and builders who require precise design specifications.

Global Market Outlook and Sustainable Growth

The global PPGI sheet market continues to expand, driven by rapid industrialization and increasing demand for energy-efficient, sustainable building materials. Asia-Pacific, particularly China, remains a dominant force in production and export due to its advanced technology, large-scale capacity, and cost-effective solutions.

As industries move toward eco-conscious construction and durable infrastructure, the role of PPGI sheets will only grow stronger. Manufacturers are now focusing on developing more advanced coatings, including anti-bacterial and self-cleaning options, to meet the evolving needs of modern architecture and manufacturing.

Conclusion

High-quality PPGI sheets represent the perfect balance between functionality, design, and sustainability. Their exceptional durability, corrosion resistance, and wide range of applications make them an essential material for today’s construction and industrial projects. With trusted suppliers delivering top-grade products that adhere to international standards, PPGI sheets continue to set benchmarks in performance and reliability across the global market. Whether used in architectural design or industrial production, these sheets remain a cornerstone of modern engineering excellence.