CRGO (Cold Rolled Grain-Oriented) silicon steel is a high-performance material widely used in the manufacturing of electrical equipment, particularly in applications that require efficient energy conversion and minimal energy loss. The unique properties of CRGO silicon steel make it an ideal choice for critical components such as transformers, motors, and inductors. Its ability to efficiently conduct magnetic flux with low core losses is crucial for improving the performance of electrical devices.

In this article, we will explore the properties, manufacturing process, and key applications of CRGO silicon steel, highlighting its role in enhancing energy efficiency in electrical steel applications.

What is CRGO Silicon Steel?

CRGO silicon steel is a specialized alloy of iron and silicon, where the silicon content typically ranges from 2% to 6.5%. The term “grain-oriented” refers to the way the steel is processed during manufacturing to align the grains in a specific direction. This orientation significantly improves the material’s magnetic properties, making it an ideal choice for electrical applications that require the efficient flow of magnetic flux, such as transformer cores and electrical motor windings.

CRGO silicon steel is mainly used in electrical steel applications where low core loss, high permeability, and minimal energy waste are critical. These properties enable electrical devices to operate efficiently and reduce operational costs.

Key Properties of CRGO Silicon Steel

The unique properties of CRGO silicon steel make it well-suited for electrical applications. These properties include:

- High Magnetic Permeability: CRGO silicon steel has a high magnetic permeability, meaning it can conduct magnetic flux efficiently. This is critical for applications such as transformers and electric motors, where the magnetic field is the driving force behind energy conversion.

- Low Core Loss: One of the main advantages of CRGO silicon steel is its ability to minimize core losses. Core losses are the energy dissipated as heat in the material when it is subjected to alternating magnetic fields. By reducing core losses, CRGO silicon steel ensures that electrical devices such as transformers and motors operate with high efficiency.

- Reduced Eddy Current Losses: Eddy currents are unwanted circulating currents induced in conductive materials by changing magnetic fields. CRGO silicon steel’s high electrical resistivity reduces these eddy current losses, which is particularly important in reducing the overall energy consumption of electrical devices.

- High Electrical Resistivity: The electrical resistivity of CRGO silicon steel further contributes to its ability to reduce energy losses during operation. This property ensures that the material can efficiently conduct magnetic flux with minimal energy dissipation.

- Grain-Oriented Structure: The process of grain orientation is a key feature of CRGO silicon steel. By aligning the grains in a specific direction, the steel’s magnetic properties are optimized, allowing for efficient magnetic flux conduction along the grain direction. This orientation enhances the material’s performance in electrical applications, especially in transformers and motors.

Manufacturing Process of CRGO Silicon Steel

The production of CRGO silicon steel involves several stages, each carefully controlled to achieve the material’s unique magnetic properties and high performance. The key steps in the manufacturing process include:

- Steel Production: The process begins with producing base steel, which is then alloyed with silicon to achieve the desired silicon content. The specific amount of silicon added determines the material’s magnetic properties.

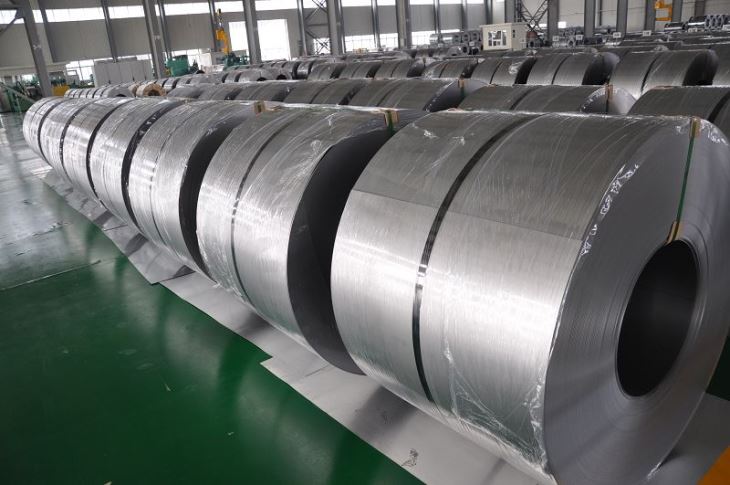

- Cold Rolling: After alloying, the steel is cold-rolled into thin sheets or strips. Cold rolling is essential for refining the steel and achieving the desired thickness and surface finish. This process also helps improve the steel’s strength and durability.

- Annealing: After cold rolling, the steel undergoes an annealing process, where it is heated to a high temperature in a controlled atmosphere. This process relieves internal stresses and helps to realign the steel’s grain structure. In CRGO silicon steel, this step is particularly crucial for creating the grain-oriented structure that enhances the material’s magnetic properties.

- Grain Orientation: During the annealing process, the grains of the steel are oriented in a specific direction. This grain orientation is critical to achieving high magnetic permeability and reducing core losses in electrical applications. The alignment of the grains ensures that the magnetic flux flows efficiently along the grain direction, optimizing the performance of electrical devices.

- Surface Treatment: To further improve the material’s performance, a thin insulation coating is applied to the surface of the CRGO silicon steel. This coating helps prevent oxidation, reduces eddy current losses, and improves the steel’s insulation properties. It also ensures that the steel maintains its high performance over time.

Applications of CRGO Silicon Steel

CRGO silicon steel is used primarily in electrical applications where high efficiency and minimal energy loss are essential. Some of the key applications of CRGO silicon steel include:

1. Transformers

Transformers are critical components in power transmission and distribution systems. They work by converting electrical energy from one voltage level to another. CRGO silicon steel is used in the cores of transformers because of its high magnetic permeability and low core loss. These properties allow transformers to operate with high efficiency, reducing energy consumption and ensuring reliable performance.

The grain-oriented structure of CRGO silicon steel is particularly beneficial in transformer applications, as it minimizes losses and enhances the transformer’s efficiency over its lifespan.

2. Electric Motors

Electric motors, which are used in everything from household appliances to industrial machinery, rely on CRGO silicon steel for efficient energy conversion. The material is used in the stator and rotor cores of motors to generate the magnetic fields that drive motor operation. The high electrical resistivity and low core loss of CRGO silicon steel ensure that motors run with minimal energy waste, improving performance and reducing operational costs.

In applications such as electric vehicles, where energy efficiency is crucial, CRGO silicon steel is especially important for optimizing motor performance.

3. Inductors and Reactors

Inductors and reactors, which are used in power supply circuits and electrical power systems, rely on the efficient conduction of magnetic fields. CRGO silicon steel’s low core losses and high magnetic permeability make it an ideal material for these components. By reducing energy losses, CRGO silicon steel helps improve the overall performance and efficiency of inductors and reactors.

4. Electric Generators

CRGO silicon steel is used in the manufacturing of electric generators, which convert mechanical energy into electrical energy. The material’s magnetic properties enhance the generator’s ability to produce electricity efficiently, reducing energy loss and improving the generator’s overall performance.

Benefits of CRGO Silicon Steel

The use of CRGO silicon steel in electrical steel applications provides several benefits:

- Energy Efficiency: The high magnetic permeability and low core loss of CRGO silicon steel ensure that electrical devices such as transformers and motors operate efficiently, reducing energy consumption and operational costs.

- Improved Performance: CRGO silicon steel’s ability to conduct magnetic flux efficiently allows electrical devices to perform at their best, with minimal energy waste and maximum output.

- Reduced Heat Generation: By minimizing core losses and eddy current losses, CRGO silicon steel helps reduce heat generation in electrical equipment, which can prolong the life of devices and prevent overheating.

- Long-Term Durability: The durability of CRGO silicon steel ensures that electrical motors, transformers, and other devices continue to function optimally over extended periods, contributing to the overall reliability of power systems.

- Cost-Effective: Although CRGO silicon steel may have a higher initial cost than conventional materials, its energy efficiency and long-term performance benefits make it a cost-effective solution for electrical applications.

Conclusion

CRGO silicon steel is a key material in the manufacturing of electrical devices that require efficient energy conversion and minimal energy loss. Its high magnetic permeability, low core losses, and grain-oriented structure make it ideal for applications such as transformers, electric motors, inductors, and generators. By enhancing the performance and energy efficiency of electrical equipment, CRGO silicon steel plays a critical role in improving the overall efficiency of power systems and reducing operational costs. Its continued use in electrical steel applications ensures that modern technology remains both efficient and sustainable.