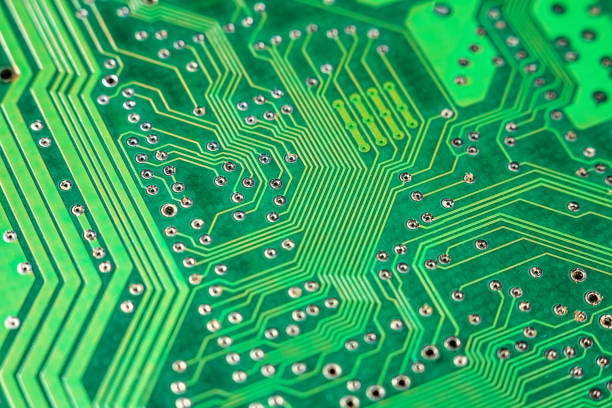

In the electronics and circuit design industry, printed circuit boards, abbreviated as PCBs, are basic components that make it possible to build complex interconnections. At the heart of every PCB lies its foundational form: the all-through-drilled electronic bare board to the blank PCB board. This paper explores the uses of blank PCB boards and the need to understand them with regards to their importance in today’s technologies.

What are blank PCB boards?

Blank PCB boards, bare PCBs, or unpopulated PCBs are the boards that require an electronic circuit design but are not processed yet. In most cases, these boards consist of a nonconducting base material like fiberglass (FR4) on which a layer of copper is added. Again, the copper layer is removed selectively to form the desired paths or tracks, which are used to interconnect the various electronic parts on the PCBs when they are completed.

Applications of Blank PCB Boards

Prototype Development:

The copper clad of PCB boards are widely applied in prototyping of electronic products. Designers and engineers utilize them to come up with new circuit designs and try them out on actual circuits before featuring them on circuits that will be made in huge numbers. The favorite feature of designing within QUCS was the opportunity to easily modify and revolutionize designs using the blank PCB board.

Custom Electronics:

The unconstrained PCB boards are applied as elements of specific electronic creations to be used in certain processes. From a specialized sensor (array) to a control board of industrial machinery to a consumer electronics device, starting from an empty PCB board enables extensive freedom in terms of both the layout and usefulness of the final design.

Research and Education:

These blank PCB boards are essential in academia, especially in research institutions where many experiments and new ideas are tested in electronics. For students and researchers, the kits are mostly very useful as they enable the users to apply circuit theory, learn soldering procedures, and investigate the performance of the components in different connections.

Low-Volume Production:

When a large number of products cannot be produced or are not profitable, blank PCB boards are utilized for developing restricted electronic products. This is particularly true in specific electronics production houses, most of which specialize in producing items of specific models and characteristics.

Benefits of Using Blank PCB Boards

- Flexibility in Design:

The separation of the conductor and the dielectric material is also perfect since the insulating material is present as a continuous layer on the bare PCB boards. There are boards in different sizes, layers, and materials that can be selected to correspond with specific design or construction projects. This flexibility continues in the selection of single-sided, double-sided, or multi-layer PCBs based on the circuit complexity.

- Cost-Effective Prototyping:

Blank PCB boards are cheaper compared to fully assembled PCBs, which is why they are preferred mostly when prototyping. This kind of tool can be very helpful for designers because they can change how they lay out a certain board and its configurations without the actual assembly of the components into each and every board layout. This cuts down on the cost; hence, the company is protected from incurring heavy losses during the experimental stages of the product.

- Enhanced Control Over the Manufacturing Process:

Starting with blank PCB boards also works in favor of manufacturers and designers, as they are more flexible throughout the manufacturing process. With external manufacturing, they can observe all the processes, including the selection of high-quality materials, the fine etching of copper traces, and the inclusion of intensive checking processes. It is one of the controls that leads to a more reliable and consistent product-end result.

- Facilitates innovation and creativity:

Easily modifiable PCB boards imply creativity since it is possible to design circuits in rather unique ways and integrate other technologies. No matter if implementing wireless communication modules, active or passive sensors, or microcontrollers, designers can unleash their creativity and produce rather innovative electronic products.

Conclusion

Printed circuit boards without components constitute the primary unit of contemporary electronics design, applicable in consumer electronics, aerospace engineering, and so on. Their outlook on application, inexpensive nature in prototyping, and provision of chances for customized designs render them crucial tools in the engineering, researching, and hobby worlds. The significance of blank PCB boards in defining the future of technologies in electronic apparatus increases with the rise in technological evolution.

Therefore, it can be concluded that, referring to the applications and advantages of blank PCB boards, it is possible to emphasize their importance in the field of electronics. So, no matter if you have just come up with a new product idea or are trying to discover the newest electronic technology, accepting the opportunities of blank PCB boards means that there is no limit.